Email:info@yasound.net

Contact:Mr.Ken

URL:www.yasound.net

Add:Puxin Hu North Road,TangXia Town ,Dongguan

City,GuangDong Province,China

- Author:

- Source:

- Date: 2014-11-28

- Views: 2499Times

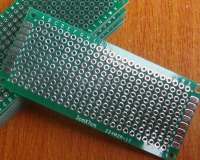

With the continuous development of the PCB industry , PCB industry practitioners also increasing. This article briefly describes what the PCB materials and production methods.

PCB basic materials are:

Substrate : Substrate were generally classify the insulation substrate , a common raw material for the electricity board , glass fiber, and all kinds of plastic plates . The manufacturer will generally PCB in a glass fiber, the fabric material, and a resin composition of the insulating portion , and then compressed to form an epoxy resin and a copper foil " adhesive film " (prepreg) use .

PCB common substrate and main ingredients are:

FR-1 ─ ─ phenolic cotton paper , which base known as Bakelite ( FR-2 higher than the economy )

FR-2 ─ ─ phenolic cotton paper ,

FR-3 ─ ─ cotton (Cotton paper), epoxy

FR-4 ─ ─ glass cloth (Woven glass), epoxy

FR-5 ─ ─ glass cloth , epoxy resin

FR-6 ─ ─ matte glass , polyester

G-10 ─ ─ glass cloth , epoxy resin

CEM-1 ─ ─ tissue paper , epoxy resin ( flame retardant )

CEM-2 ─ ─ tissue paper , epoxy resin ( non-plenum )

CEM-3 ─ ─ glass cloth , epoxy resin

CEM-4 ─ ─ glass cloth , epoxy resin

CEM-5 ─ ─ glass cloth , polyester

AIN ─ ─ aluminum nitride

SIC ─ ─ SiC

Metal coating

In addition to the metal coating on the substrate outside the wiring , which is the base line with the place for soldering electronic components .

Metal coating are used : copper, tin ( thickness is usually from 5 to 15μm), tin-lead alloy ( or tin-copper alloy , the solder , the thickness is usually from 5 to 25μm, Sn content of about 63%) , gold ( generally plated with the interface ) , silver ( generally only plated on the interface , or in the whole is silver alloy) .

Production methods are:

Subtractive method (Subtractive), is the use of chemicals or mechanical board blank ( i.e. covered with a complete piece of metal foil circuit board) where it is not removed , the remaining areas of the circuit is needed .

Addition (Additive), is now generally pre- coated on a thin copper on a substrate , covering the photoresist (D / F), by exposure to UV light and then developed, where the need to expose the circuit board and by plating official line on copper thickness thickening to the required specifications , and then coated with a layer of anti- etch resist - metal thin tin , and finally removing photoresist ( this process is called to film ) , and then resist the foil layer etched away .

Lamination method : production of a multilayer printed circuit board is one of the methods . After the package is in production on the inner outer , outer layer and then subtract method or additive method for processing. Repeating the operation of lamination method can be obtained and then the multilayer printed wiring board multi- sequential lamination method compared .

Panel plating

Pattern plating

Fully additive method

Part Addition

ALIVH

B2it